Looking for the Most Reliable Print Quality? A Well-Established Print Shop Delivers Vibrant Prints Every Time

Looking for the Most Reliable Print Quality? A Well-Established Print Shop Delivers Vibrant Prints Every Time

Blog Article

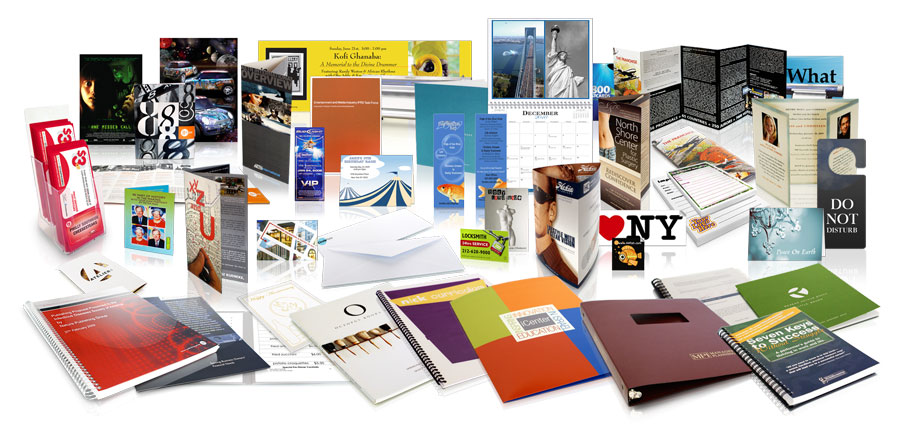

Comprehending Exactly How Printing Services Work to Provide Phenomenal Quality for Your Catalogs and books

An in-depth understanding of printing solutions is crucial for achieving extraordinary quality in publications and catalogs. The journey begins with pre-press preparations, where key choices concerning format and color improvement are made. Picking the suitable printing method-- whether electronic or countered-- serves as a foundation for meeting details task requirements. The selection of top notch products and the execution of strenuous proofing processes play crucial duties in the final outcome. Yet, the subtleties of completing touches usually determine the total impact of your published products, raising the inquiry of how to navigate these complexities successfully.

The Printing Process Explained

The printing procedure is a diverse procedure that transforms electronic styles right into substantial products. It generally starts with pre-press prep work, where files are formatted and maximized for printing. This phase consists of shade modification, design adjustments, and proofing to ensure that the end product fulfills top quality assumptions. As soon as the data prepare, the following step involves picking the suitable printing method, such as electronic, balanced out, or flexography, each with its very own benefits relying on the job's requirements.

Complying with the option of the printing strategy, the production stage commences. For offset printing, plates are created to move ink onto paper, while electronic printing utilizes digital documents to print straight onto substrates. Print Shop. During this stage, careful focus is paid to color accuracy and picture resolution to preserve the integrity of the original design

Post-press processes such as reducing, binding, and completing are vital for the final discussion of published products. These processes make sure that publications, brochures, and other published products are not just visually enticing but additionally useful and durable. The entire printing procedure, from pre-press to post-press, calls for skilled experts to provide outstanding high quality and fulfill customer expectations successfully.

Selecting Top Quality Materials

Choosing high quality products is a vital facet of the printing process that straight influences the final item's durability, look, and overall impact. The selection of paper, ink, and binding materials plays a considerable duty in establishing just how your publication or magazine is perceived by its audience.

When it involves paper, consider elements such as finish, weight, and structure. A heavier paper not only really feels more substantial however additionally improves the aesthetic high quality of published pictures. Distinctive alternatives can add a tactile dimension, making the reading experience a lot more interesting. In addition, picking acid-free paper can prevent yellowing and degeneration gradually, guaranteeing your work stands the test of time.

The choice of ink is similarly important. Premium inks supply sharp details and vibrant shades, which are essential for making pictures and images stick out. Eco friendly inks can appeal to eco-conscious customers, including worth to your product.

Finally, the binding materials have to be long lasting yet adaptable, permitting convenience of use. Choices like excellent binding or hardcover can considerably affect the durability and visual of the completed product. Ultimately, picking high quality products will certainly improve the general presentation and effectiveness of your printed products.

Printing Techniques and Technologies

While numerous printing methods and technologies have developed for many years, each approach serves distinct functions and offers special advantages that can considerably affect the quality and cost-effectiveness of published products. Among one of the most typical strategies are digital printing, offset printing, and gravure printing.

Digital printing is recognized for its versatility and rate, making it optimal for short runs and on-demand printing. On the other hand, balance out printing, which makes use of a plate to transfer ink onto paper, is liked for large volume runs due to its cost efficiency and high-quality output.

Gravure printing, commonly utilized for long-run magazines, entails inscribing pictures onto a cyndrical tube. This method provides exceptional photo top quality and is extensively used for magazines and packaging. Each of these modern technologies has specific applications, and comprehending their toughness is essential for picking the appropriate printing service, guaranteeing that the end product fulfills both budgetary and visual demands.

Proofing and Quality Assurance

Efficient proofing and top quality control are indispensable elements in the printing process, ensuring that the final product aligns with the intended layout and meets client expectations. This phase begins with the development of evidence-- preliminary versions of the published material-- which can be either physical or digital. These evidence enable customers to assess designs, colors, and total style before mass production starts.

This includes meticulous checks at various phases of the printing process. Printing specialists assess color accuracy, picture resolution, and uniformity throughout batches.

Eventually, reliable proofing and strenuous quality assurance not only boost customer satisfaction however additionally minimize waste, time, and expenses related to reprints. By focusing on these elements, publishing solutions can provide books and catalogs that really reflect the vision and assumptions of their clients.

Last Touches for Presentation

The last touches for presentation are crucial in elevating the general visit site effect of printed Full Report materials, guaranteeing they not just share details however likewise captivate the target market. This phase encompasses numerous components that enhance both visual appeals and performance, contributing to a refined product.

One considerable element is the choice of binding, which can substantially affect the usability and aesthetic charm of directories and publications. Choices such as perfect binding, saddle sewing, or spiral binding need to line up with the intended usage and target market choices. Furthermore, the option of covers-- be it soft or difficult-- adds an extra layer of class.

In addition, ending up strategies such as spot, lamination, or embossing UV covering can offer texture and aesthetic passion, making the printed products more interesting. These functions not only protect the product however likewise develop a memorable tactile experience for readers.

Final Thought

In summary, the printing procedure encompasses several important phases that jointly add to the manufacturing of high-grade books and directories. From careful pre-press prep work to the option of appropriate printing methods and materials, each aspect plays an essential function in the last output. Strenuous proofing and top quality control actions make certain consistency throughout the procedure, while thoughtful complements enhance the overall presentation. article A comprehensive understanding of these parts is important for achieving outstanding results in published products.

An extensive understanding of printing solutions is crucial for accomplishing phenomenal high quality in catalogs and publications. For offset printing, plates are produced to move ink onto paper, while digital printing utilizes electronic files to publish directly onto substrates. The whole printing operation, from pre-press to post-press, needs experienced specialists to deliver exceptional top quality and meet customer assumptions efficiently.

Digital printing is recognized for its flexibility and speed, making it excellent for short runs and on-demand printing.Reliable proofing and high quality control are important elements in the printing procedure, making sure that the final item straightens with the designated layout and fulfills client assumptions.

Report this page